As President of the Canadian Centre for Raw Materials Display Inc. (CACERMDI), it is an honor to join in the celebration of National Indigenous Peoples Day. This day, dedicated to recognizing the rich cultures, contributions, and histories of First Nations, Inuit, and Métis peoples, also provides an opportunity to reflect on the intersections between Indigenous communities and the raw materials sector in Canada.

A Rich Legacy of Stewardship

Indigenous peoples in Canada have a profound and enduring connection to the land and its resources. For thousands of years, they have demonstrated sustainable practices in harvesting raw materials, embodying a deep respect for the environment. This legacy of stewardship offers invaluable lessons as we navigate the complexities of resource management in the 21st century. Traditional ecological knowledge, passed down through generations, can inform and enhance contemporary approaches to sustainable development.

Partnerships for Sustainable Development

The raw materials sector plays a significant role in Canada’s economy, and Indigenous communities are increasingly becoming pivotal stakeholders in this industry. Across the nation, Indigenous-led enterprises are engaging in mining, forestry, and other resource-based ventures, fostering economic growth and self-sufficiency. These partnerships not only create jobs and training opportunities but also ensure that development projects are conducted in an environmentally responsible and culturally respectful manner.

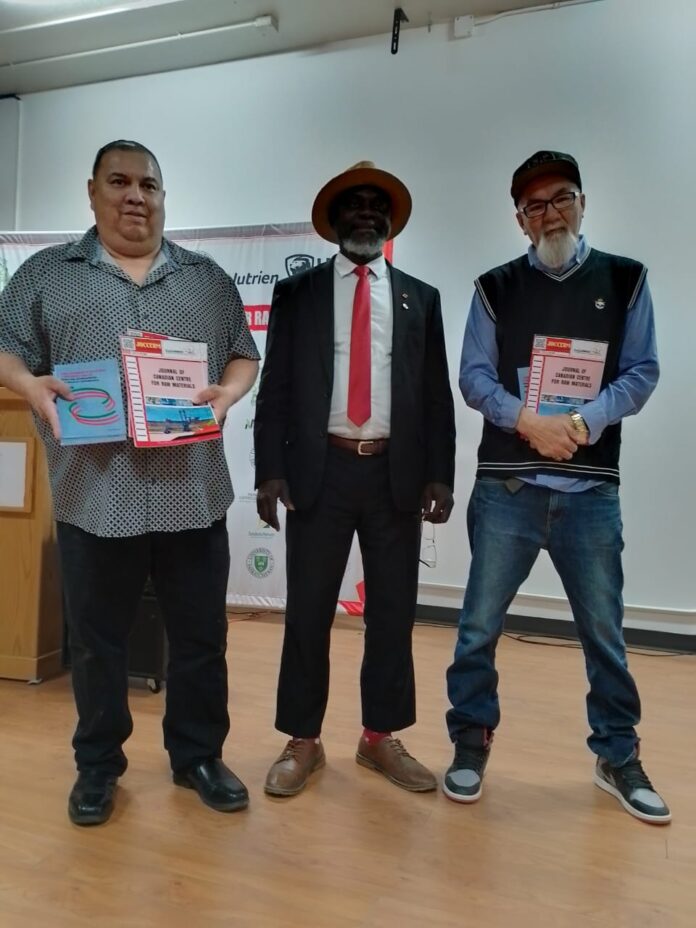

At CACERMDI, we are committed to supporting these initiatives by facilitating dialogue, providing educational resources, and promoting best practices in the raw materials sector. Our goal is to empower Indigenous communities to fully realize the benefits of their natural resources while preserving their cultural heritage and protecting their lands.

Educational and Economic Empowerment

Education is a cornerstone of empowerment. By investing in educational programs and vocational training, we can equip Indigenous youth with the skills needed to thrive in the raw materials industry. CACERMDI is proud to collaborate with Indigenous educational institutions and community organizations to offer scholarships, internships, and mentorship opportunities. These initiatives aim to nurture the next generation of Indigenous leaders in the sector.

Moreover, economic empowerment through resource development can significantly enhance the quality of life in Indigenous communities. Revenue generated from resource projects can be reinvested in vital infrastructure, healthcare, and educational services, contributing to the overall well-being and resilience of these communities.

Celebrating Achievements and Looking Forward

National Indigenous Peoples Day is also a time to celebrate the remarkable achievements of Indigenous peoples in the raw materials sector. From innovative mining projects to sustainable forestry practices, Indigenous-led initiatives are setting new standards for the industry. These success stories serve as powerful examples of what can be achieved through collaboration, respect, and shared vision.

As we look to the future, CACERMDI remains dedicated to fostering strong partnerships with Indigenous communities. We believe that by working together, we can build a more sustainable and inclusive raw materials industry that honors the past while embracing the future.

Conclusion

National Indigenous Peoples Day is a reminder of the vital contributions that Indigenous peoples make to the fabric of our nation. It is also an opportunity for all of us in the raw materials sector to reaffirm our commitment to supporting Indigenous communities in their pursuit of economic empowerment and sustainable development.

At CACERM-DI, we are inspired by the resilience, wisdom, and vision of Indigenous peoples. We are committed to walking alongside them on this journey, ensuring that their voices are heard, their rights are respected, and their futures are bright.

In celebrating National Indigenous Peoples Day, let us honor the heritage, recognize the contributions, and support the aspirations of Indigenous peoples across Canada. Together, we can create a legacy of prosperity and sustainability for generations to come.

Author: Leo Ekhaguere, President

Canadian Centre for Raw Materials Display Inc. (CACERMDI)

Toll-Free 18662750224

This article highlights the significant relationship between Indigenous communities and the raw materials sector, celebrating their contributions and outlining CACERMDI’s commitment to supporting Indigenous-led initiatives.